Gator-Laid@ 9-Part Braided Wire Rope Sling

Basic Info

Model No.: Gator-Laid@

Product Description

Model NO.: Gator-Laid@ Material: Steel Fixed Form: Bolt Type Rope Core Type: Steel Core Shape: Eye-Eye Sling Color: as Request Trademark: Ropers Specification: 82B HS Code: 7312900000 Type: Wire Rope Sling Lifting Capacity: >6T Lifting Eye Type: Sofy Eyes Power Source: Hydraulic Certification: SGS, CE, RoHS, ISO 9001 Customized: Available Transport Package: Roll Origin: China Features:

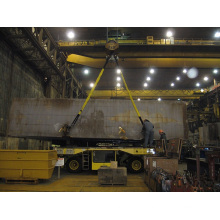

• Heavy lift sling with great flexibility

• 12 part eyes stacked parallel and wrapped with buffer webbing

• Heavy gauge stainless steel tag made in accordance with ASME B30.9 & API RP2C

• 6x19 class IWRC EIP bright Wire Rope supplied standard on 1/4" - 1-1/8"

• 6x37 class IWRC EIP bright wire rope supplied standard on 1-1/4" and larger

• D/d of the eye equals 1 to 1

• D/d of the body equals 5 to 1

• Proof testing available upon request

• Design factor 5 to 1

How to order:

• Specify part number and length

• Customer must specify eye length

Note

• Capacities shown include both paths and are for one complete sling

• Sling rating based on fittings of equal or greater capacity

• Conforms to ASME B30.9, Chapter 6, NAVFAC P-307 section 14.7.4.3, and the Cordage Institute Roundsling standard

WARNING:

Follow OSHA, ASME B30.9 and Manufacturer's Guidelines. Can fail if damaged, misused, or overloaded. Inspect before use. Use

only if trained. Do not exceed rated capacity. Protect from contact with edges. DEATH or INJURY can occur from improper use or

maintenance.

Contact us if you need more details on Wire Rope Sling. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Sling、Lifting Sling. If these products fail to match your need, please contact us and we would like to provide relevant information.

• Heavy lift sling with great flexibility

• 12 part eyes stacked parallel and wrapped with buffer webbing

• Heavy gauge stainless steel tag made in accordance with ASME B30.9 & API RP2C

• 6x19 class IWRC EIP bright Wire Rope supplied standard on 1/4" - 1-1/8"

• 6x37 class IWRC EIP bright wire rope supplied standard on 1-1/4" and larger

• D/d of the eye equals 1 to 1

• D/d of the body equals 5 to 1

• Proof testing available upon request

• Design factor 5 to 1

How to order:

• Specify part number and length

• Customer must specify eye length

| Composed of 9 parts of EIP Rope | Part Number | Actual Finished Diameter | Eye Length | Rated Capacities in Short Tons | Approximate Wt./Ft. Lbs. |

| 1/8" | 1L010101 | 1/2" | 8" | 1.4 | 1.0 | 2.8 | .26 |

| 3/16" | 1L010102 | 5/8" | 12" | 3.0 | 2.2 | 6.0 | .59 |

| 1/4" | 1L010103 | 1" | 16" | 4.8 | 3.6 | 9.6 | .99 |

| 5/16" | 1L010104 | 1-1/4" | 18" | 7.5 | 5.6 | 15.0 | 1.56 |

| 3/8" | 1L010105 | 1-1/2" | 20" | 10.5 | 7.8 | 21.0 | 2.19 |

| 7/16" | 1M010106 | 1-3/4" | 22" | 14.6 | 10.9 | 29.2 | 3.15 |

| 1/2" | 1M010107 | 2" | 24" | 19.1 | 14.3 | 38.2 | 4.14 |

| 9/16" | 1M010108 | 2-1/4" | 26" | 24.1 | 18.0 | 48.2 | 5.31 |

| 5/8" | 1M010109 | 2-1/2" | 28" | 29.6 | 22.2 | 59.2 | 6.48 |

| 3/4" | 1M010110 | 3" | 30" | 42.3 | 31.7 | 84.6 | 9.36 |

| 7/8" | 1M010111 | 3-1/2" | 35" | 57.3 | 42.9 | 114.6 | 12.78 |

| 1" | 1M010112 | 4" | 40" | 74.4 | 55.8 | 148.4 | 16.65 |

| 1-1/8" | 1M010113 | 4-1/2" | 45" | 93.6 | 60.2 | 187.2 | 21.06 |

| 1-1/4" | 1M010114 | 5" | 50" | 115 | 86.2 | 230.0 | 26.01 |

| 1-3/8" | 1M010115 | 5-1/2" | 55" | 138.2 | 103.6 | 276.4 | 31.50 |

| 1-1/2" | 1M010116 | 6" | 60" | 164.1 | 123.0 | 328.2 | 37.44 |

| 1-3/4" | 1M010118 | 7" | 70" | 220.3 | 165.2 | 440.6 | 51.03 |

| 2" | 1M010120 | 8" | 80" | 285.1 | 213.8 | 570.2 | 66.51 |

| 2-1/4" | 1M010122 | 9" | 90" | 355.6 | 266.7 | 711.2 | 84.24 |

| 2-1/2" | 1M010124 | 10" | 100" | 434.8 | 326.1 | 869.6 | 104.00 |

| 2-3/4" | 1L010125 | 11" | 110" | 519 | 327 | 870 | 140 |

| 3" | 1L010127 | 12" | 120" | 612 | 459 | 1224 | 166 |

| 3-1/2" | 1L010131 | 14" | 140" | 812 | 609 | 1624 | 227 |

Note

• Capacities shown include both paths and are for one complete sling

• Sling rating based on fittings of equal or greater capacity

• Conforms to ASME B30.9, Chapter 6, NAVFAC P-307 section 14.7.4.3, and the Cordage Institute Roundsling standard

WARNING:

Follow OSHA, ASME B30.9 and Manufacturer's Guidelines. Can fail if damaged, misused, or overloaded. Inspect before use. Use

only if trained. Do not exceed rated capacity. Protect from contact with edges. DEATH or INJURY can occur from improper use or

maintenance.

Contact us if you need more details on Wire Rope Sling. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Sling、Lifting Sling. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Lifting Solutions

Other Products

Hot Products

Handmade Polypropylene Chemical Fiber Net3 Strand Plaited Red Nylon RopeRS Approved 12 Strand Kevlar Rope12 Strand UHMWPE Rope (Fall Prevention Device) for LifeboatsGl Approved 6-Strand Cross-Laid Atlas Mooring RopeCable for BMU / Window cleaning machine wire ropeGator-Laid@ 9-Part Braided Wire Rope SlingSuper Strength Hmpe Heavy Lifting-Optima-7s RopeHigh Quality Maritime M-P08 Ropes for MarineUltra High Moleoular Weight Polyethylene RopesHigh Quality Accessory Cord for RopeHertz for Offshore Oil Platform Mooring RopeDirect 8mm Special Rope. Nylon Rope Large Congyou Mooring RopeDouble-Layer Stranded Fiber Ropes Mooring Rope for Mixed Batch Offshore Operation12 -Strand Chemical Fiber Ropes Mooring Rope Polypropylene, Polyester Mixed8-Strand Chemical Fiber Ropes Mooring Rope PP Rope Polyester Rope PE Rope